Why Injection Molding Design is Critical for Successful Product Development

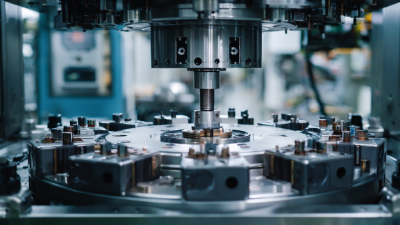

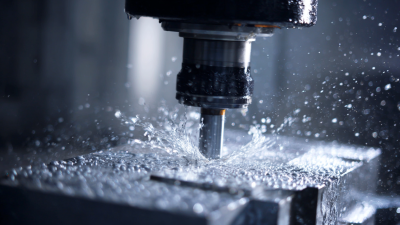

In the realm of product development, the significance of effective injection molding design cannot be overstated. As one of the most widely used manufacturing processes for producing plastic parts, injection molding plays a pivotal role in transforming innovative concepts into tangible products. The design phase is critical, as it directly influences the functionality, aesthetics, and cost-effectiveness of the final product. A well-thought-out injection molding design not only optimizes material usage but also streamlines production, ensuring that products meet quality standards while minimizing waste.

Moreover, the intricate interplay between design elements such as part geometry, material selection, and manufacturing techniques can drastically affect the production timeline and overall project success. Poor design decisions can lead to production delays, increased costs, and ultimately, compromised product quality. Therefore, understanding the importance of injection molding design is essential for engineers and designers alike, as it lays the foundation for successful product realization and market competitiveness. By prioritizing optimal design in the injection molding process, companies can enhance their product development strategies, resulting in innovative, efficient, and high-quality offerings.

Read more »

By:Ethan - December 24, 2025

By:Ethan - December 24, 2025

By:Aria - December 19, 2025

By:Aria - December 19, 2025

By:Ethan - December 14, 2025

By:Ethan - December 14, 2025

By:Aria - December 11, 2025

By:Aria - December 11, 2025

By:Aria - December 6, 2025

By:Aria - December 6, 2025

By:Ethan - December 1, 2025

By:Ethan - December 1, 2025

By:Ethan - November 26, 2025

By:Ethan - November 26, 2025

By:Aria - November 22, 2025

By:Aria - November 22, 2025

By:Ethan - November 19, 2025

By:Ethan - November 19, 2025

By:Lila - November 12, 2025

By:Lila - November 12, 2025

By:Aria - November 9, 2025

By:Aria - November 9, 2025

By:Lila - November 4, 2025

By:Lila - November 4, 2025

By:Aria - October 25, 2025

By:Aria - October 25, 2025

By:Ethan - October 20, 2025

By:Ethan - October 20, 2025

By:Aria - October 16, 2025

By:Aria - October 16, 2025