In today's competitive manufacturing landscape, understanding the benefits of injection mold making is crucial for businesses aiming for success. Injection mold making not only enhances product quality and consistency but also streamlines production processes, ultimately reducing time-to-market and costs. By utilizing advanced technologies and precision engineering, companies can produce complex shapes and intricate designs that meet specific consumer demands. Moreover, the scalability of injection molding allows businesses to increase their production volumes efficiently, catering to growing market needs. This guide will explore the various advantages of injection mold making and provide actionable insights on how to effectively integrate this process into your business strategy, ensuring you stay ahead in the ever-evolving industry. Embracing injection mold making can lead to innovative product development, improved operational efficiency, and increased profitability, making it an essential component for long-term business success.

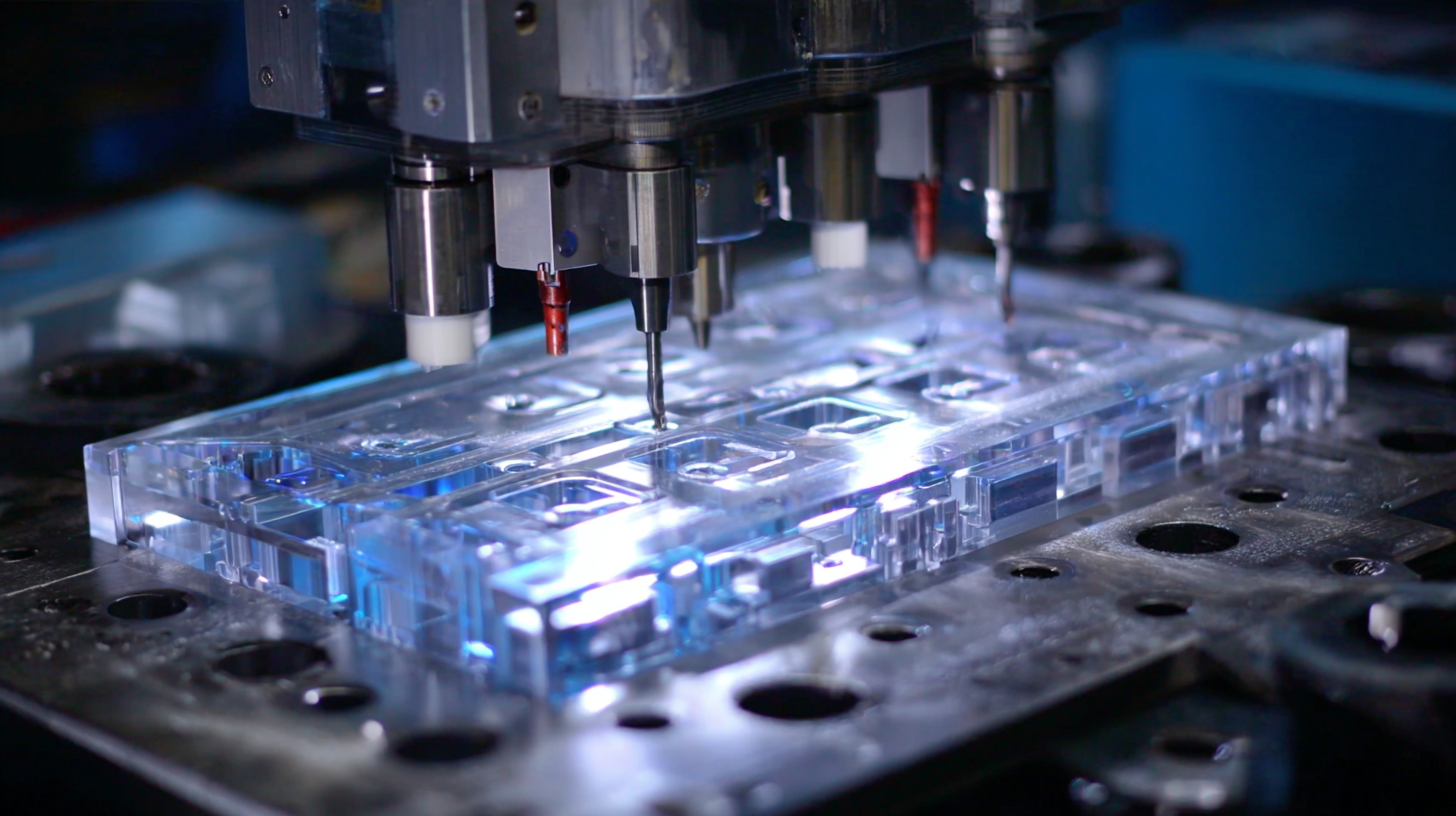

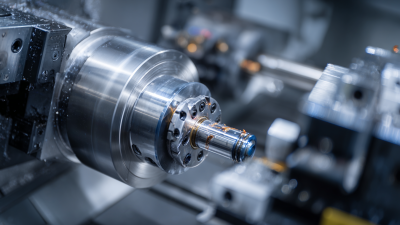

Injection mold making serves as a pivotal catalyst for enhancing product development efficiency across various industries. By utilizing advanced technologies and precision engineering, businesses can streamline the process of transforming design concepts into tangible products. This efficiency is crucial for companies aiming to reduce time-to-market, enabling them to respond swiftly to consumer demands and industry trends. The ability to produce high-quality molds reliably permits designers and engineers to focus on innovation rather than logistics.

Injection mold making serves as a pivotal catalyst for enhancing product development efficiency across various industries. By utilizing advanced technologies and precision engineering, businesses can streamline the process of transforming design concepts into tangible products. This efficiency is crucial for companies aiming to reduce time-to-market, enabling them to respond swiftly to consumer demands and industry trends. The ability to produce high-quality molds reliably permits designers and engineers to focus on innovation rather than logistics.

Moreover, the precision inherent in injection mold making not only improves production efficiency but also significantly reduces waste. By ensuring that products are manufactured with exact dimensions, businesses can minimize material losses and decrease the need for rework, thus optimizing resource utilization. This sustainable approach not only contributes to cost savings but also aligns with the growing emphasis on environmentally responsible manufacturing practices. Consequently, injection mold making emerges as a strategic investment for businesses looking to enhance both their efficiency and sustainability in product development.

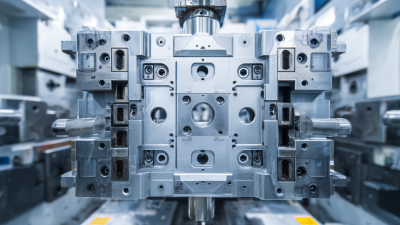

Injection mold making is a pivotal process for many businesses seeking to enhance their production efficiency while simultaneously reducing costs. By investing in high-quality molds, companies can achieve significant savings of 20-30% on production expenses. This reduction is primarily due to the efficiency of the injection molding process, which allows for high-volume, low-cost production of uniform parts and products. The initial investment in mold making can be offset by the long-term savings and increased productivity it facilitates.

Tips to maximize cost-efficiency in injection mold making include selecting the right materials for your molds, which can significantly impact durability and longevity. Additionally, partnering with experienced mold makers who understand your specific industry needs can lead to customized solutions and innovations that further streamline production. It's also beneficial to regularly evaluate your production run sizes and consider optimizing your designs to minimize waste and enhance the effectiveness of the injection molding process.

By focusing on these aspects, businesses can harness the full potential of injection mold making, leading to not only cost savings but also improved product quality and time-to-market advantages.

Precision in injection mold manufacturing plays a pivotal role in enhancing product quality, which is crucial for the success of any business. The process of injection molding relies heavily on the accuracy of the mold design and fabrication. A well-crafted mold ensures that the final products exhibit consistent dimensions, smooth surfaces, and precise features. This level of precision not only reduces the rate of defects but also minimizes material wastage and production costs, leading to higher profitability.

Furthermore, the relationship between precision and product quality extends beyond mere aesthetics. In industries such as automotive, medical, and consumer electronics, precision is synonymous with functionality and safety. Components that are manufactured with meticulous attention to detail meet stringent industry standards and regulations. As a result, businesses that prioritize high-precision injection mold making enhance their reputation, build customer trust, and foster loyalty. By investing in advanced technologies and skilled craftsmanship, companies can produce superior products that not only meet but exceed market expectations.

Rapid prototyping has become essential for businesses aiming to shorten their time-to-market, and injection mold making plays a crucial role in this process. Recent advancements in low-volume injection molding services have allowed companies to create high-precision prototypes efficiently. This is particularly beneficial in industries like medical devices, where speed and accuracy are paramount. By leveraging advanced injection molding techniques, businesses can quickly iterate on their designs, ensuring they meet market demands and regulatory standards without the lengthy delays often associated with traditional manufacturing methods.

Moreover, the integration of 3D printing technologies with injection mold making further accelerates product development. This combination allows manufacturers to rapidly produce molds and adapt to the ever-changing market landscape. 3D-printed molds not only expedite the R&D phase but also enhance local manufacturing capabilities, enabling businesses to maintain a competitive edge. As the global market for industrial molds continues to expand, embracing innovative processes in mold making will be vital for sustaining business success and driving new product innovations.

| Aspect | Description | Benefits |

|---|---|---|

| Cost Efficiency | Reduction in manufacturing costs through mass production. | Lower unit costs drive profitability. |

| Quality Consistency | High precision molds ensure uniformity across products. | Increased customer satisfaction and repeat orders. |

| Time-to-Market | Rapid prototyping capabilities lead to faster product launches. | Gain competitive advantage through quicker releases. |

| Material Versatility | Wide range of materials can be used for unique product requirements. | Ability to cater to diverse market needs. |

| Design Flexibility | Ability to create complex and intricate designs. | Enhanced product offerings and differentiation. |

Injection mold making has become increasingly important not only for the economic success of businesses but also for its role in promoting sustainability within manufacturing. According to a report from the American Society of Plastics Engineers, adopting injection molding can reduce energy consumption by up to 30% compared to traditional manufacturing methods. This substantial reduction in energy usage contributes to lower carbon footprints, making injection mold techniques more environmentally friendly.

Moreover, modern injection molding processes utilize recyclable materials, which can be reused for new products. The Ellen MacArthur Foundation suggests that transitioning to a circular economy through effective waste management can result in savings of up to $630 billion annually for the global plastics industry. By focusing on sustainable materials, businesses can not only meet increasing consumer demand for eco-conscious products but also position themselves as leaders in sustainability.

Tips: When implementing injection mold techniques, prioritize suppliers who focus on sustainable practices and materials. Additionally, regularly assess your production processes to identify areas where energy efficiency can be improved. Consider investing in technology that supports recyclability and waste reduction to further enhance the sustainability of your manufacturing operations.

This chart illustrates the key environmental benefits associated with injection mold techniques, highlighting the importance of sustainability in manufacturing processes. The percentages reflect potential improvements in energy efficiency, material waste reduction, recyclability, process efficiency, and product longevity.

Copyright © 2025 The Toolroom Inc. All Rights Reserved.

Website Design St Louis by IQComputing