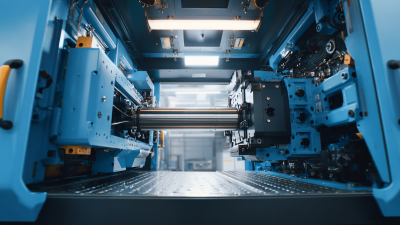

In the fast-evolving landscape of modern manufacturing, rubber molding has emerged as a pivotal technique that enhances efficiency and product quality across various industries. According to a report by Smithers Pira, the global market for rubber products reached approximately $25 billion in 2021, with projections indicating continued growth driven by sectors such as automotive, healthcare, and consumer goods. This surge can be largely attributed to the advantages provided by rubber molding, which enables the production of complex shapes with high precision and consistency, reducing waste and optimizing resource utilization.

Rubber molding techniques, including compression, injection, and transfer molding, offer manufacturers the flexibility to create bespoke solutions tailored to specific application needs. Notably, a study by Grand View Research highlights that the injection molding segment alone is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2022 to 2030. This trend underscores the increasing reliance on rubber molding as a critical component of manufacturing strategies. By understanding and leveraging the benefits of rubber molding, manufacturers can improve product performance, enhance sustainability, and maintain a competitive edge in an increasingly demanding market.

Rubber molding techniques play a crucial role in modern manufacturing, providing a versatile solution for producing high-quality rubber components tailored to industry-specific needs. The molding process, whether through injection, compression, or transfer methods, allows manufacturers to create intricate designs and complex geometries with precision and efficiency. According to a report by Grand View Research, the global rubber molding market is expected to reach USD 9.6 billion by 2027, highlighting the growing demand for rubber molded products across various sectors, including automotive, aerospace, and consumer goods.

One of the primary advantages of rubber molding is its ability to integrate multiple materials, enhancing product durability and functionality. For instance, the use of thermoplastic elastomers (TPE) in rubber molding can introduce properties like increased chemical resistance and improved weatherability. The Technical Association of the Rubber Industry (TARIC) has noted that innovations in rubber formulations and processing technologies have led to significant improvements in product performance. Additionally, with the rise of automation in manufacturing, rubber molding processes can achieve higher throughput and reduce production costs, making them increasingly attractive for manufacturers looking to optimize their operations.

Rubber molding has become a vital process in modern manufacturing, offering significant advantages that enhance product durability. One of the primary benefits of rubber molding is the superior resistance of rubber materials to wear and tear. Products manufactured through this process can withstand extreme conditions, including temperature fluctuations, chemical exposure, and mechanical stress. This inherent durability extends the lifespan of products, making them more reliable in various applications across industries.

Moreover, rubber molding allows for precise customization, enabling manufacturers to create parts with specific properties that cater to their unique requirements. The process can produce components with varying levels of hardness, flexibility, and resilience, ensuring that the end products perform optimally in their intended environments. This level of adaptability significantly contributes to product longevity by minimizing the risk of failure and reducing maintenance needs, ultimately leading to more cost-effective solutions for businesses.

Rubber molding has become an essential technique in modern manufacturing processes due to its profound impact on cost efficiency and productivity. By utilizing rubber as a primary material, manufacturers can significantly reduce production costs compared to traditional materials. The flexibility of rubber allows for complex designs and customized solutions, enabling production lines to minimize waste and maximize output. This adaptability not only lowers material expenses but also streamlines the manufacturing process, leading to faster turnaround times and improved overall efficiency.

Moreover, advancements in rubber molding technology contribute to heightened productivity levels in various industries. The implementation of systems such as the Shuttle Mold system can effectively double the productivity of production cycles by capitalizing on cooling times, showcasing the potential for significant gains in efficiency. As manufacturers increasingly adopt rubber molding techniques, the benefits extend beyond mere savings; they also foster innovation within product development and enable companies to stay competitive in a rapidly evolving market. The combined effects of cost reduction and enhanced productivity position rubber molding as a pivotal element in optimizing modern manufacturing strategies.

Rubber molding is increasingly recognized for its environmental benefits in modern manufacturing processes. As industries worldwide strive for sustainability, the adoption of rubber molding techniques has shown promising results. According to a recent report by the Rubber Manufacturers Association, utilizing rubber molding can lead to a reduction in waste by up to 30% compared to traditional manufacturing methods. This is primarily due to the superior material efficiency and the low scrap rate associated with rubber molding, which maximizes resource use and minimizes environmental impact.

Additionally, rubber molding processes often incorporate recycled materials, contributing further to sustainability goals. A survey by the International Rubber Study Group indicated that approximately 25% of rubber used in molding worldwide is derived from recycled sources. This not only conserves natural resources but also reduces landfill contributions, significantly lowering the carbon footprint of manufacturing operations.

**Tip:** When considering rubber molding for your manufacturing needs, explore suppliers that prioritize the use of eco-friendly materials and practices. This can enhance your company's sustainability profile while reducing costs associated with waste disposal and raw material procurement.

**Tip:** Always assess the lifecycle impact of the materials used in rubber molding. Opting for processes that utilize renewable resources can further improve your product's environmental footprint, aligning with consumer demand for greener products.

| Dimension | Parameter | Benefit |

|---|---|---|

| Material Efficiency | Reduction in Waste | Optimizes resource usage and minimizes production waste. |

| Energy Consumption | Lower Energy Use | Rubber molding processes require less energy compared to traditional methods. |

| Recyclability | Post-Consumption Recycling | Used rubber can be recycled, reducing landfill impact. |

| Emissions | Reduced VOCs | Minimized volatile organic compound emissions during production. |

| Supply Chain Impact | Local Sourcing Opportunities | Encourages local material sourcing, enhancing local economies. |

Rubber molding stands out as a versatile manufacturing process, particularly when compared to traditional methods like injection molding and compression molding. One of the key advantages of rubber molding is its ability to create complex geometries with high precision. This is particularly beneficial in industries that require intricate designs, such as automotive and medical device manufacturing. Unlike injection molding, which can be limited by the material's viscosity and flow characteristics, rubber molding allows for better material distribution within molds, ensuring more uniform product characteristics.

Furthermore, the efficiency of rubber molding in producing high volumes of parts cannot be overstated. While processes like compression molding are slower and may involve longer cycle times, rubber molding offers a quicker turnaround, making it ideal for mass production. Additionally, rubber molding can accommodate a variety of rubber compounds, allowing manufacturers to select materials tailored to specific environmental conditions or mechanical properties. This adaptability not only optimizes performance but also reduces waste, making rubber molding a sustainable choice in modern manufacturing landscapes.

Copyright © 2025 The Toolroom Inc. All Rights Reserved.

Website Design St Louis by IQComputing